螺紋鋼

螺紋鋼

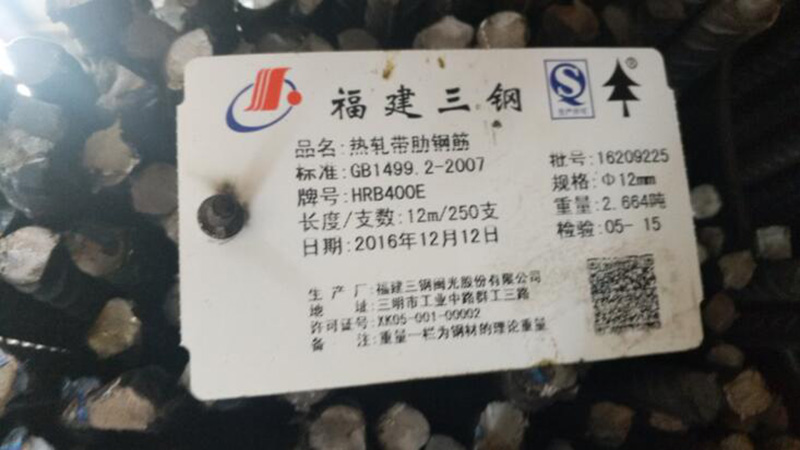

龍巖長青建材是集倉儲、物流、配送、加工為一體的綜合性民營企業(yè),明價(jià)經(jīng)營福建三鋼“閩光”牌建筑鋼材。;

公司成立于2013年,坐落在福建省武平縣工業(yè)園區(qū),公司自建有大型室內(nèi)倉庫及鋼筋加工場,常年庫存鋼材五千余噸,經(jīng)過短短幾年的摸索與經(jīng)驗(yàn),業(yè)界朋友不斷寄予厚望并給予極大的支持和關(guān)心,在全體同仁的共同努力下,各項(xiàng)業(yè)務(wù)日趨規(guī)模與穩(wěn)健,創(chuàng)建以來履約守信,在供與求的市場經(jīng)濟(jì)中,我們形成了一個(gè)良好的營銷體系。

公司實(shí)行現(xiàn)代企業(yè)管理制度,本著“明價(jià)銷售,誠信共贏”的經(jīng)營理念,“求實(shí)、守信、創(chuàng)新、敬業(yè)”的企業(yè)精神。力爭打造武平周邊區(qū)域最有價(jià)值的鋼鐵服務(wù)品牌,只需關(guān)注微信公眾號:“長青建材”...